The spindle is among the most crucial components in modern manufacturing where accuracy and reliability cannot be compromised. When it comes to carving aerospace-grade metals or fine-tuning high-tolerance components for medical devices the machining spindle can be the unseen force behind accuracy, speed, and consistency.

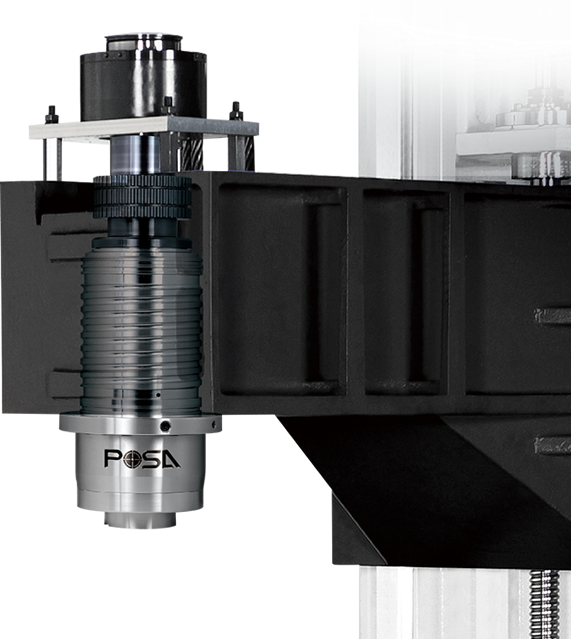

At the forefront of this specialized industry are elite spindle manufacturers like POSA Machinery, who are redefining what performance and durability look like in industrial machining environments.

Image credit: posa-spindle.com

Why the Spindle Is the Heart of the Machine

Every CNC machine is only as great as its spindle. The spindle powers the tool with a high degree of precision, stability, and torque. Spindles that have been misaligned or poorly designed can lead to damaged parts or malfunctions, which can damage the machine, and decrease the tool’s life. They may also cause disruption to the process of production.

This is where precision technology spindles can make all the differences. Precision spindles aren’t mass-produced parts that can be thrown together quickly. They are precisely engineered, calibrated, and tested to perform in extreme conditions.

POSA more than a Spindle Manufacture

While many spindle manufacturers claim to provide high precision yet few offer the depth of experience and engineering knowledge that POSA Machinery has acquired over time. POSA is well-known for its strict internal testing procedures, dedication to international standards, and their ability to create solutions that are performance-driven which meet the requirements of various industries.

POSA spindles are used in a range of machines, ranging from vertical and horizontal machining centres to tool grinding machines. Every spindle goes through a rigorous R&D procedure that is focused not just on the performance of the spindle, but on its reliability over time as well as thermal stability.

The Evolution of the CNC Lathe Spindle

The last few years have witnessed significant innovation in the CNC spindle. No longer just a rotating axis, today’s spindles integrate sensors cooling systems, sensors, and sophisticated balancing systems. POSA CNC spindles offer an excellent illustration. They combine high-speed capabilities and exceptional torque together with a high degree of rigidity and precision, permitting machinists work with both delicate metals and soft materials. These spindles, which are constructed of premium steel and advanced ceramic bearings, reduce the expansion of thermal energy while maintaining precise tolerances throughout long runs. This kind of durability translates directly into improved quality of the part and reduced downtime.

Tailored Machining Spindles for Real-World Needs

It’s impossible to locate a machining machine which is universally applicable, particularly for industries like aerospace, automotive, and die & mould manufacturing. POSA is aware that each industry is unique and has its own set of needs, be it spindle speed in terms of load capacity, speed, or environmental resistance. This is why they provide customized spindle configurations that are based on the specific needs of each client. Whether it’s designing a spindle to mill vertically or integrating a high-frequency spindle into an efficient system, POSA provides the flexibility and engineering support that modern manufacturers need.

More Than Machines: A Promise to Craftsmanship

POSA is not only about its spindles, but also the philosophy which drives them. The company is dedicated to combining creativity and innovation. The designers work closely with customers as they listen to their needs and continually adapt their offerings to stay ahead of market trends and demands. In an era where the machine’s uptime, accuracy and repeatability can make or break the production line, having the correct spindle partner is crucial.

Final Thoughts

The future of manufacturing relies not only on faster machines but also on the components that are more intelligent and reliable. POSA Machine is a great example of what spindle makers can accomplish when they combine their technical knowledge with a focus on customer service. A good spindle can make or break your project. Whether it is high-performance CNC lathe spindle which will last for years, a heavy duty spindle made to handle machining or a highly precise precision spindle.