Machining has always been about precision and speed. However, in today’s highly competitive manufacturing industry, efficiency is now a necessity. The tools you choose to use have an impact on your profits, whether you are producing parts for automotive, aerospace and high-tech electronic items. High-speed drill, tungsten carbide based end mills, and threading insert have made a significant impact.

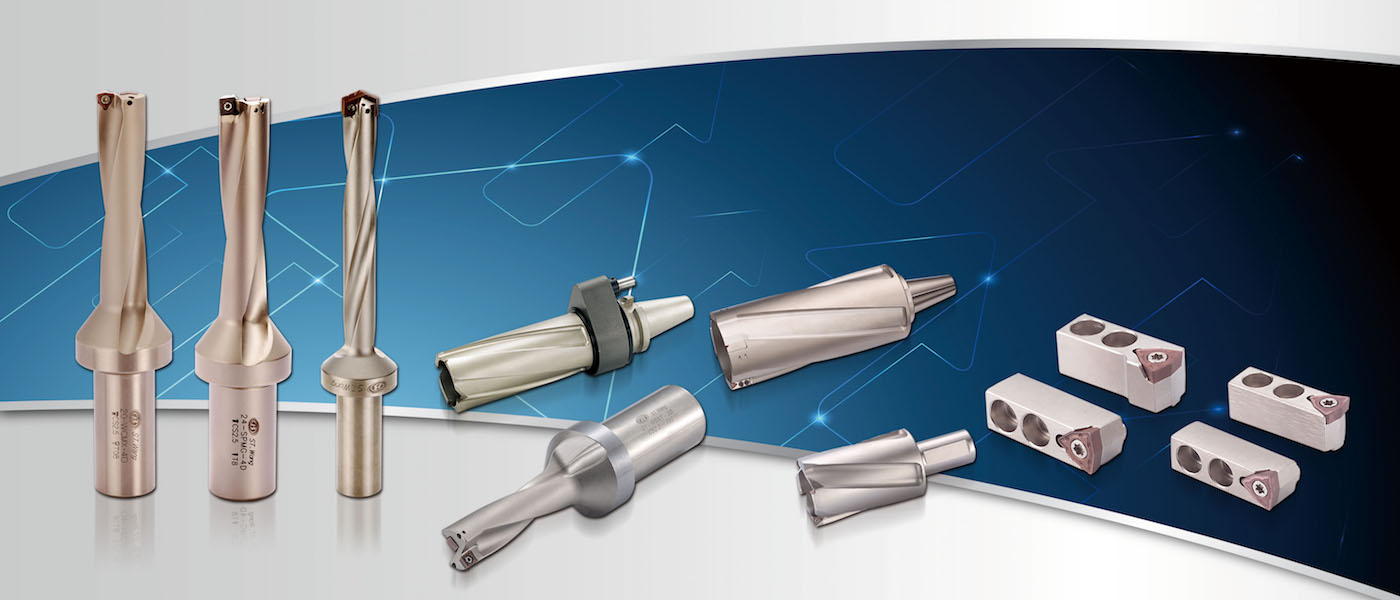

Image credit: stwang-tw.com

These aren’t just upgrades of outdated tools. These new tools give you an efficient method of working, which reduces downtime, lowers costs and provides better results using less effort. We’ll take a closer at how they can aid manufacturers cut faster, drill more efficiently and finish faster.

Indexable Drills: More Holes, Less Hassle

Drilling holes of a large size used to be expensive and long-lasting. The drills were prone to wear out they needed sharpening and in some cases, they reduced production speeds. That’s why more machinists are switching to the indexable drill. You can swap out inserts rather than the whole tool when it becomes dull.

The effectiveness of indexable drills is what sets them apart. They’re made for long runs, high-end performance and simple maintenance. With the option of replacing inserts help cut down on waste, reduce inventory of tools and ensure that your equipment runs longer. SHANG TZANG WANG ENTERPRISE CO., LTD, offers high-end disposable core-stay drills which provide reliable performance even in large-diameter applications. For shops that perform repeated hole machining this upgrade will save hours of downtime every week.

High Speed Drills – Designed to Modern Demands

In a work environment where time is the most valuable commodity, high speed drills are designed to be fast, without compromising accuracy. They’re able to work with tough materials and fast cycles. They’re used in everything from precision medical parts to high-volume automotive parts.

Modern high-speed drills have optimized flute designs and cutting-edge coatings which resist thermal buildup, minimize friction, and prolong time of use. This means fewer breaks as well as fewer replacement tools and more components. Making the switch to a high-speed drill is an ideal solution for anyone who is frustrated by breaking a tool in mid-cycle.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

In the realm of milling, tungsten carbide’s end mills are among the most productive of the workshop floor. These end mills are known for their resistance to heat and hardness. They also can break through tough materials with no loss of edge sharpness. No matter if you’re roughing out massive sections or working on tight edges, these machines provide reliable results that users can rely on.

Their versatility is what really makes tungsten carbide end mills so unique. The different coatings, helix angles, and flute count can be customized for a wide variety of tasks, ranging from aluminum to titanium. Carbide endmills are ideal for those who need to keep their precision in check while maintaining durability.

Threading Inserts: Tiny Tools, Big Impact

The process of creating threads might seem like an insignificant part of a procedure, but this is actually one of the most important. A weak thread could ruin the quality of a product. It’s essential to select threading inserts of the highest quality. These small, replaceable inserts are engineered to cut external or internal threads with extreme precision and repeatability.

The threading inserts for threading are more consistent than traditional taps or dies. They provide identical results even after many cycles. The tool can be indexed towards the next cutting point if one of the edges is dull. There’s no need to remove it or replace. This is a simple affordable, simple, and cost-effective method of doing this. Machinists value threading inserts not only for their speed, but for their durability. You can rest assured that the threads you use are going to fit perfectly the first time. There is no rework not even a rework. No concern about the possibility of rejecting components.

Bottom Line

In the modern world of machining, you can’t afford to lose time. The most efficient shops of today are focusing on smarter and more adaptable machines. The cutting tools aren’t only more precise, they also make workflows easier and reduce changes, in addition to extending the useful life of the tool. The result? Less time spent troubleshooting and more time focusing on the production of high-quality components. In a market where greater demand and a tighter margin are commonplace tools that work more effectively give companies the competitive edge.